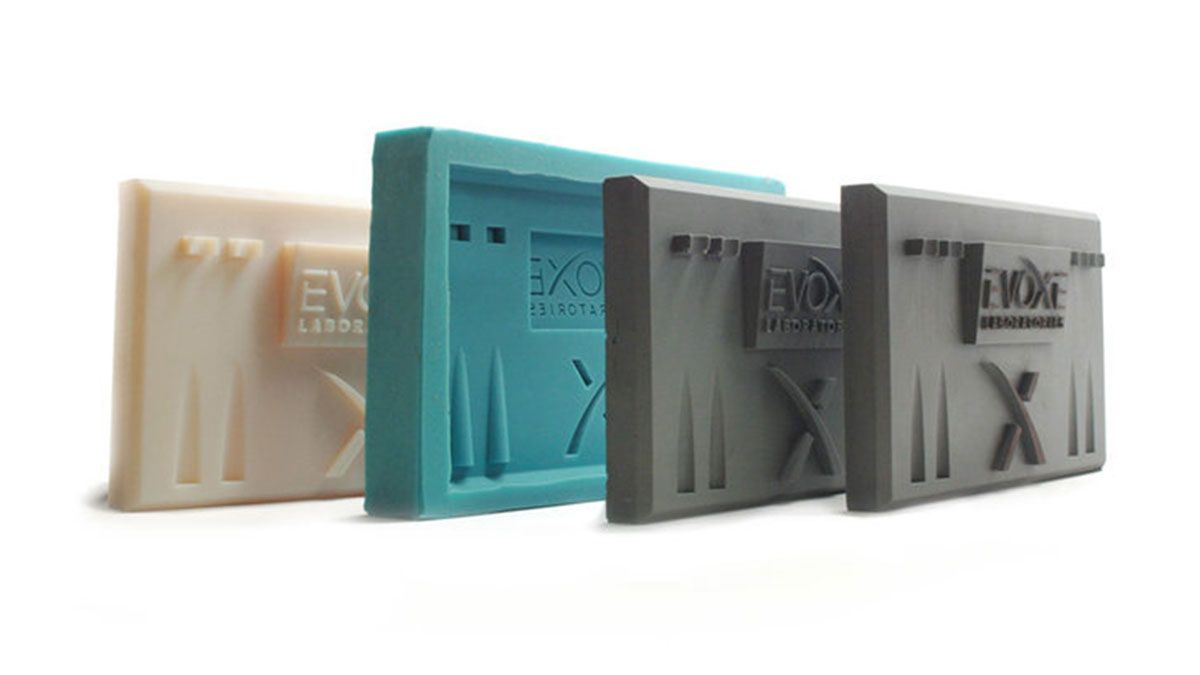

Silicone Rubber Molds

from 3D Printed Parts

Silicone rubber molds are a great way to produce multiple copies of 3D Printed parts in epoxy resin, plaster, polyurethane foam, wax, soap, or concrete.

Get A Quote

Get A Quote

Overview

Applications

How to Order

Examples Gallery

Get connected to a project manager, and take the next step with your prototyping or fabrication needs.

Get a Quote