Model + Scenic Painting

Pantone Color Matching

and Custom Finishes

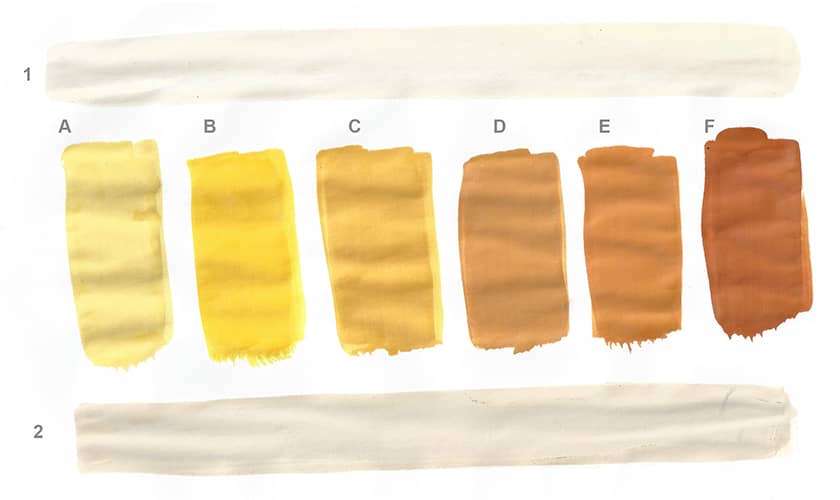

Turn your 3D Printed parts into flawless, presentation-ready models with any color or finished surface appearance.

Get A Quote