Overview

Applications

How to Order

Silicone Moldmaking: Overview

Summary: What is a Silicone Rubber Mold?

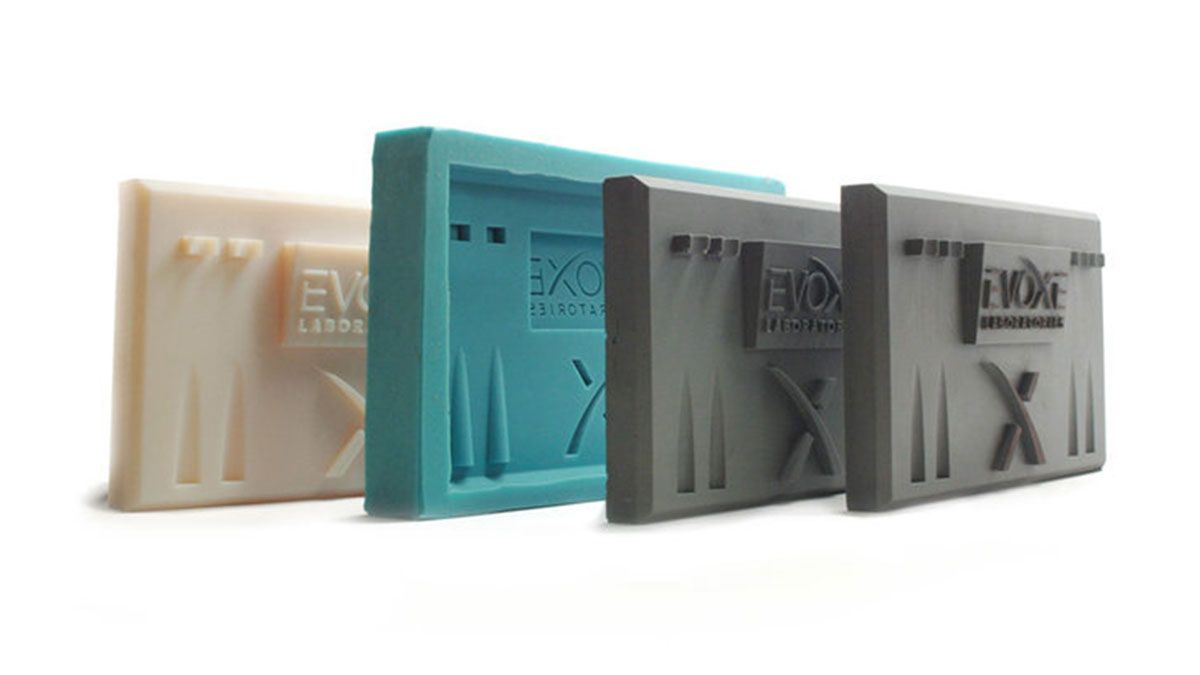

A silicone mold is a block of rubber with an internal empty cavity. This empty cavity has the precise negative shape of an object which is to be cast by pouring material into the cavity. Silicone molds are made using a "master" 3D Printed part.

A one-piece silicone dump mold is a single square of silicone with an exposed cavity on top. Casting material is poured into the cavity until it reaches a flat surface, flush with the flat top of the dump mold. Silicone dump molds are used for creating items with flat bottom surfaces and positively angled geometry without undercuts: soap molds, candle molds, and chocolate molds, for example.

If your part is more complex than a dump mold allows for, a two-part silicone mold can be created. This is a block of rubber that is sliced into two halves, with a top spout tube for pouring in casting material. Two-part silicone molds are commonly used for more complex geometry like mechanical parts, statues, and sculptures.

Applications

Silicone molds are widely used for casting a variety of materials, including urethane, epoxy, and resin. The molds themselves are typically created by pouring liquid silicone over a master model, using various techniques to achieve detailed and reusable molds. This process allows for the precise reproduction of complex shapes and fine details, making silicone molds ideal for prototyping, small batch production, and artistic applications. Additionally, silicone can withstand the heat generated during the curing process of resin, maintaining its integrity.

What kinds of materials can be poured into a silicone mold?

Creating parts from a silicone mold is commonly called Vacuum Casting, RTV Molding, RTV Casting, or simply: casting. The material poured into the silicone mold -- the material in which your copied parts are made -- is called casting material.

Popular casting materials that work with silicone molds are urethane resin plastic, epoxy resin, plaster, polyurethane foam, wax, soap, and concrete.

How does it work?

The process requires a physical 3D Printed part, called the "master." The master part is a 3D Printed part made in high-resolution SLA Resin, and is perfectly smooth so as to allow for a high-quality mold and smooth cast parts.

To produce your silicone mold, we will first 3D Print your master part in SLA Resin, and then create a silicone mold from that part.

What do I need to provide in order to get a silicone mold made?

You will need to provide your 3D Model / CAD files in one of the following formats: STL, OBJ, STEP/STP, or IGES/IGS. Your 3D Model will be 3D Printed in SLA Resin, and this master part will be used to create your silicone rubber mold. We must 3D Print your master part -- physical parts are not accepted from customers to serve as the mold master.

If you don't have a 3D Model CAD file, we offer 3D Scanning and 3D Design services to create a 3D Model for you, based on a physical sample part or drawings/dimensions/images that you provide.

How many cast parts can I make from a single silicone mold?

Your silicone mold is affected by the material curing inside the mold, as well as the mechanical stress of removing each cast part from the mold. Generally speaking, silicone molds are good for casting 30-50 copies if you're using a hard casting material like epoxy or urethane resin. If you're using a soft material like wax, you can expect your mold to have a higher yield before noticeable degradation.

It is possible to continue using your mold to cast any quantity of parts, but you can expect to start seeing visible signs of mold degradation on your cast parts as you continue to cast out higher quantities.

How long does it take to get my silicone mold?

Since this is a two-step process involving 3D Printing and moldmaking, the lead-time to deliver a finished silicone rubber mold is ~2 weeks.

Injection Molding Alternative

Why Choose Silicone Mold Casting Over Injection Molding?

When it comes to producing high-quality prototypes, custom parts, or low-to-medium volume production runs, silicone mold casting stands out as a smart alternative to traditional injection molding. While injection molding is ideal for mass production, it requires significant investment in tooling and setup, making it less practical for projects with lower quantities or frequent design changes.

Silicone mold casting, especially when paired with urethane casting services, offers a cost-efficient and flexible solution for startups, product developers, and anyone looking to create production quality parts without the high upfront costs. The process begins with a 3D printed master pattern, created using the additive manufacturing process, which allows for rapid design iterations and optimal surface detail. This master is then used to form a silicone mold, capturing even the most intricate features, sharp corners, and distinct halves of your design. Inquire about the process for creating the original master pattern, such as using high-resolution 3D printing, to ensure the best results.

One of the key advantages of silicone molding is its ability to produce cast urethane parts with a wide range of material properties, from rigid to flexible, clear to opaque. Whether you need clear parts for visual models, durable opaque parts for functional testing, or prototypes with varying wall thickness, silicone molds can deliver. The casting process is highly versatile, accommodating complex geometries that might be challenging or cost-prohibitive with injection molding. Silicone's soft, elastic nature allows for easy removal of the finished piece without damage.

For low volume production, silicone mold casting is both cost effective and time-saving. The molds themselves are produced quickly and at a fraction of the cost of injection molding tools, making it easy to create high quality prototypes or small batches of final products. This is especially valuable for projects where the desired quantity is limited, or where the design may evolve over time. RTV molding is a quick and cost-effective option for prototype molding and pre-production testing, further enhancing the efficiency of the process.

Additionally, the casting services available through silicone molding allow for a range of finishing options. Cast parts can be painted, coated, or left with a matte or glossy finish, depending on your needs. The cured silicone molds are durable enough to produce multiple parts, yet flexible enough to release even complex shapes without damage. To enhance their durability, mold release spray can be applied to silicone molds before use.

In summary, if your project requires flexibility, rapid turnaround, and production quality parts at a manageable cost, silicone mold casting is an excellent choice. By leveraging urethane casting, silicone molds, and the latest in additive manufacturing, you can create high quality prototypes and final parts with optimal surface detail—without the commitment and expense of traditional injection molding. For low volumes, custom features, and fast design cycles, silicone mold casting is the essential, cost-efficient alternative.