Overview

Applications

How to Order

Custom Fabrication: Overview

Summary: What is Custom Fabrication?

Custom Fabrication describes the process of starting with an idea or description of a finished physical piece, coming up with a custom service workflow to produce that piece, and executing the workflow to completion.

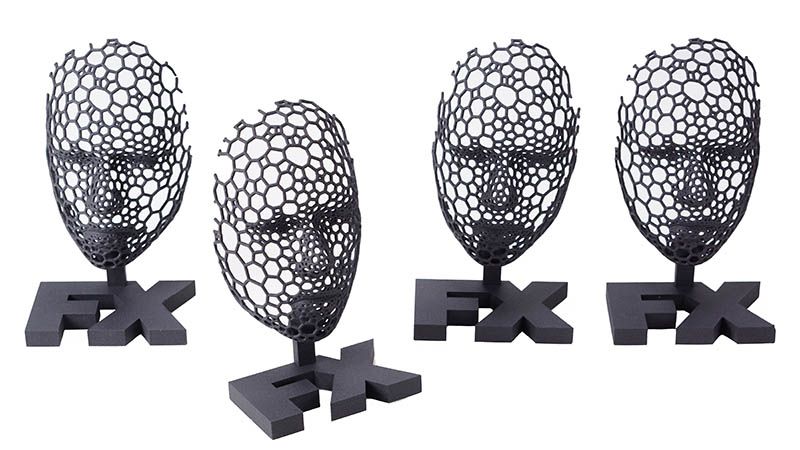

The overall process is the same whether you need a single custom trophy, a 10' tall display piece, or 250 custom promotional items for a marketing initiative. Each Custom Fabrication project involves a unique set of services in a specific order; our job is to determine what those services are, and then to perform them to completion.

Our production process leverages the latest advancements in 3D printing technology to deliver high-quality results. We use advanced technology to 3D print a wide range of materials, including plastics, metals, and elastomers, suitable for various industrial and aerospace applications. Materials used in 3D fabrication also include ceramics, foam, and concrete, further expanding the possibilities for innovative designs.

Our services are available at an affordable price, making professional 3D print solutions accessible for all. Using a 3D fabrication service can accelerate product development and offer significant cost savings, making it an efficient choice for businesses and individuals alike.

What kinds of things can you make?

Here's a list of some of the types of projects we've run through our Custom Fabrication process: custom trophies, props and wardrobe elements for Film / Television / Commercials, experiential elements for live events, branded signage, step-and-repeats for special events, props for still photography, executive gifts, jewelry, various objets d'art, one-of-a-kind sculptures, large-scale dioramas, "exploded-view" product models, tradeshow display models, custom chess sets...and even custom soap molds.

The list is pretty varied, but the common thread between all of these types of projects is this: our customers need a reliable partner who can figure out the details and get things done on time, and to a high quality standard. Many of the items we create end up on camera for broadcast media like commercials, massive live + televised events, or print ads -- so things have to look perfect. And that's what we strive to deliver.

How does it work?

Start off by submitting a request online, and be sure to include a good description of what you want to make, along with any project-specific files or reference images that show things similar to what you're looking to make.

We'll review your request and get back to you with next steps -- typically, the next step after we receive your online request is to have a phone call to go over the project in more depth.

After we fully understand your goals and any important deadlines, we'll propose a concrete service workflow -- a Project Plan -- that will lead to an end result that meets your needs.

How long does it take?

We do our best to work within your deadlines, and it's not uncommon to get a request that requires delivery within a matter of days or even next-day. If you don't have a specific deadline and need something made which requires design, fabrication, and finishing: you can expect it to take anywhere from 2 - 6 weeks. It all depends on what you need to make.